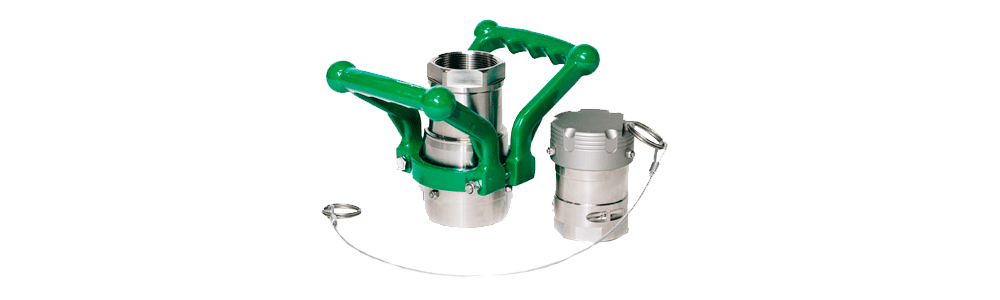

The Dry Cryogenic Coupling (LNG coupling) consist of a “tank” unit wich is a type of a non-return valve and a “hose” unit with a valve driven by an internal cam curve to open both valves at the same time. Operation is a single action using a straight forward turning motion to connect the couplings and open flow path. An initial push and turn action on the hose unit provides engagement with the tank unit, thus locking and sealing the two units together. Further rotation opening the internal valves, thereby allowing full flow with a minimum of pressure drop.

A selectivity (code) system allows the system to be used to a wide range of cryogenic liquefied gases without any risk of failure owing to “human error”.

Applications – Cryogenic (LNG) Couplings

- Container discharge

- Fuel bunkering

- Loading/unloading of tank trucks, rail tankers and ship tankers

- Vapor recovery lines

Advantages with Dry Cryogenic Couplings, MannTek LNG Couplings:

Easy to handle

- Push and turn – free flow.

- Turn and pull – closed.

Safe

- The valve cannot be opened until the unit is coupled and closes automatically when disconnecting.

Environmentally friendly

- Accidental spillage eliminated.

Reliability

- No loss or spillage of liquids at connection or disconnection.

MWP 16 Bar - 6" (DN150) to 8" (DN200)

with 5 time safety factor

Others on request.